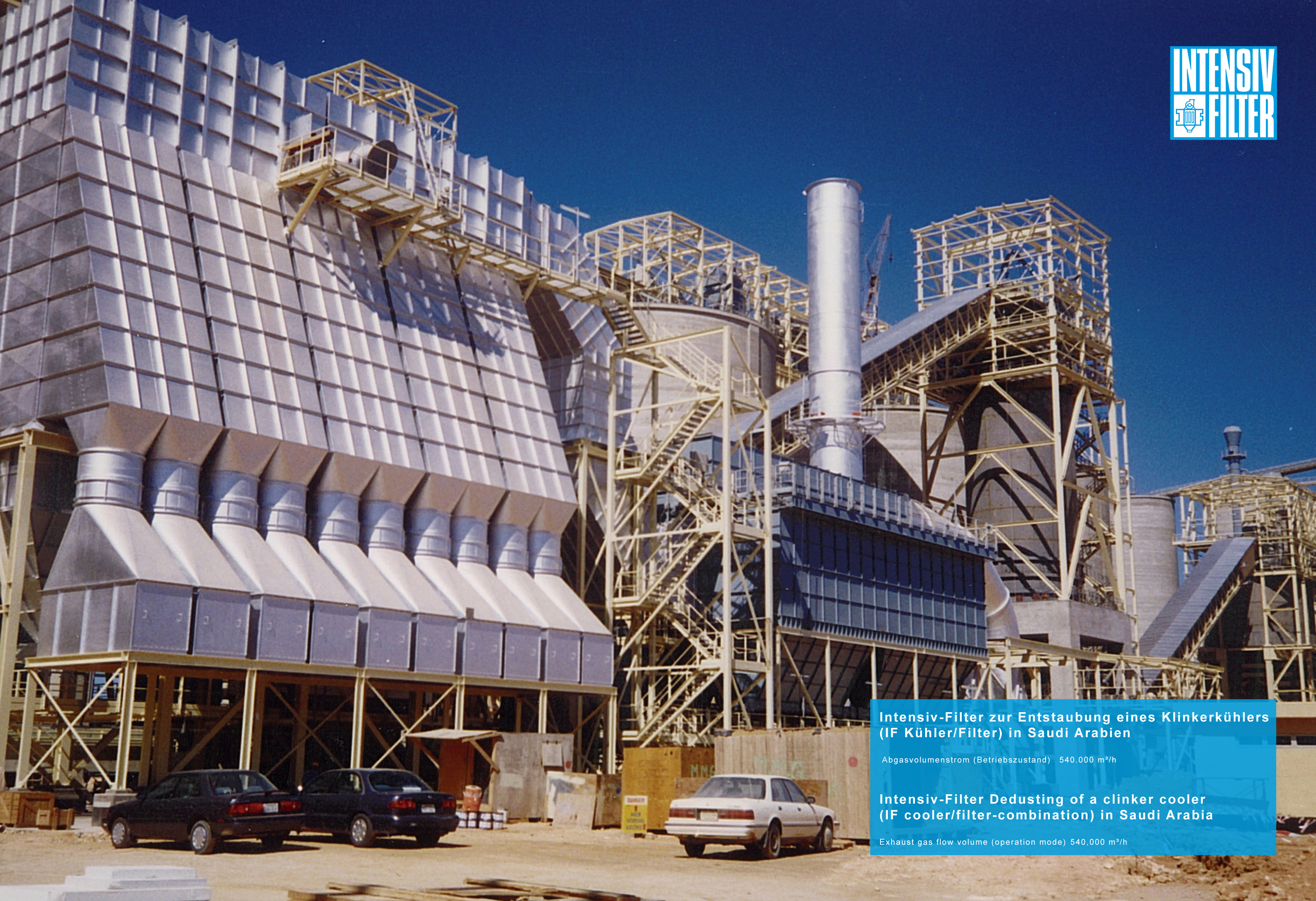

German Engineering

Planning a New Cement Plant?

What can go seriously wrong if you choose the wrong bag filter system.

🚫 No Site Support 🏗️

Small install errors. Lifetime performance loss.

🚫 Built for Average, Not Peaks 📉

Runs fine… until production matters most.

🚫 Wrong Filter Media 🧵🔥

Dust stays. Pressure rises. Energy bleeds

🚫 Weak Pulse Cleaning 💨⚠️

Dust stays. Pressure rises. Energy bleeds.

Trusted by Global Cement Leaders

Get Your Baghouse Efficiency Audit

⏰ Only 3 Priority Audit Slots Available

Where a Cement Plant Quietly Bleeds Money Every Year

Cement baghouses don’t fail loudly — they drain profit quietly.

💰 Financial Drain

High filter replacement costs

⚠️ Compliance Risk

Unstable emissions & penalty exposure

⏱️ Production Loss

Downtime during filter change

⚡Energy Waste

High fan power due to excess ΔP

| Losses don’t happen once — they happen across multiple hidden parameters.— 5,000 TPD Line | ||

|---|---|---|

| 🔧 Loss Area | 💰 Annual Impact | 📉 What Drives the Loss |

| 🧵 Bags & Maintenance | $0.5M / Year | Frequent bag failures & replacements |

| ⏱️ Production Downtime | $1.1M / Year | Shutdowns during choking & bag change |

| ⚡ Fan Energy OPEX | $3.7M / Year | High ΔP → Excess fan power consumption |

| ⚖️ Compliance Risk | $0.6M / Year | Emission exceedance & penalties |

🚨 TOTAL LOSSES = 5.9M / YEAR 🚨

The IFH Solution

Built for cement plants. Partnered beyond installation.

Built to Protect Production — Not Just Capture Dust.

Our German-engineered baghouse systems are designed to deliver:

🟢 Stability

Fewer emission spikes — even at peak loads.

🛡️ Durability

Extend filter bag life under abrasive cement dust

⚡ Efficiency

Reduce fan energy through low, stable pressure drop

🔄 Continuity

Eliminate chronic downtime linked to dust choking

| Metric | Typical Baghouse (BEFORE) | IFH Optimization (AFTER) |

|---|---|---|

| Filter Bag Life | 6–12 Months | 24–36+ Months |

| Emission Level | 30–150 mg/Nm³ | Up to <5 mg/Nm³ |

| Pressure Drop (ΔP) | 180–220 mmWC | 100–120 mmWC Stable |

| Air Consumption | 100% Baseline | 30–40% Reduction |